BINZEL MIG TORCH EVO PRO MB24 4m-012.0372.1

$242.20 Price (Excluded GST)

BINZEL MIG TORCH EVO PRO MB24 4m-012.0372.1

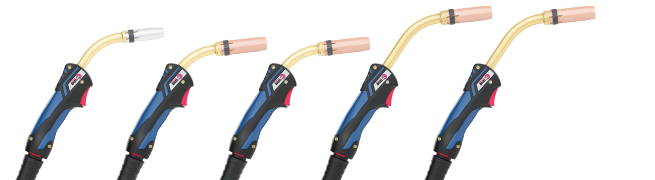

BINZEL MIG TORCH EVO PRO MB

MB EVO PRO. The standard redefined ?

The?MB EVO PRO?torch series represents a totally new concept in welding torch design, form and function. Unique ergonomics, following extensive research, provide a greater sense of control, enabling the welder to feel as ?one? with his torch. The trigger position, trigger design and ball joint construction guarantee optimum balance and comfort in all welding positions.

Tough working conditions are to be expected when MIG/MAG welding. Despite their lower weight and sophisticated design, the new MB EVO PRO torch line sets new benchmarks for strength and durability. Featuring newly designed, more robust fittings and improved space inside the handle for ease of servicing. Technology for professionals.

Air cooled?MB EVO PRO welding torches feature the reduced weight ?BIKOX? LW? cable assembly, for even better handling and scientifically proven reduced operator fatigue, in all welding positions. Improved handling and reduced strain have been shown to have a measurable impact on weld seam quality.

- Proven ?MB? wear parts ? for long, economic service life.

- Genuine two-component handle ? robust and ergonomic.

- Optimum trigger position and tapered handle design ? for precise predictable handling.

- Unique internal geometry for air cooled torches ? enabling a cooler grip with maximum mechanical strength.

- Low weight BIKOX? (LW) ? offering weight reduction of up to 34 %.

- Robust, optimized central connector.

The appeal of?liquid cooled?MB EVO PRO torches is further enhanced due to the redesigned cooling concept and selected material combination. Improved front end cooling increases wear part service life and realises extra performance reserves, enabling welding at higher power outputs.

- Highest quality ?MB? wear parts combined with optimized torch cooling ? for maximum service life.

- Genuine two-component handle ? robust and ergonomic.

- Optimum trigger position and tapered handle design ? for precise predictable handling.

- Simplified constructions easies repair through the provision of greater space for maintenance.

- High performance hoses with a special protective fabric ? enhancing flexibility and comfort.

- Robust, optimized central connector with protected hose guide.

MIG/MAG Welding Torches MB EVO PRO, air cooled

Technical data (EN 60 974-7):

| Type: | MB EVO PRO 15 | MB EVO PRO 24 | MB EVO PRO 25 | MB EVO PRO 26 | MB EVO PRO 36 |

| Rating | |||||

| CO2: | 180 A | 250 A | 230 A | 270 A | 320 A |

| Mixed gases M21*: | 150 A | 220 A | 200 A | 240 A | 290 A |

| Duty Cyle (%): | 60 | 60 | 60 | 60 | 60 |

| Wire ? (mm): | 0.6 – 1.0 | 0.8 – 1.2 | 0.8 – 1.2 | 0.8 – 1.2 | 0.8 – 1.2 |

* according to DIN EN ISO 14175

Rated using power source with VDE standard volt/amp characteristic (U=14+0.05xl). When pulse welding, reduce rating by 35%.

MIG/MAG Welding Torches MB EVO PRO, liquid cooled

Technical data (EN 60 974-7):

| Type: | MB EVO PRO 240 D | MB EVO PRO 401 | MB EVO PRO 401 D | MB EVO PRO 501 | MB EVO PRO 501 D |

| Rating | |||||

| CO2: | 325 A | 475 A | 450 A | 575 A | 550 A |

| Mixed gases M21*: | 300 A | 425 A | 400 A | 525 A | 500 A |

| Duty Cycle (%): | 100 | 100 | 100 | 100 | 100 |

| Wire ? (mm): | 0.8 – 1.2 | 0.8 – 1.2 | 0.8 – 1.2 | 1.0 – 1.6 | 1.0 – 1.6 |

* according to DIN EN ISO 14175

Rated using power source with VDE standard volt/amp characteristic (U=14+0.05xl). When pulse welding, reduce rating by 35%. Recommended cooling capacity of water recirculator approx. 800 W. To protect cable assembly components from excessive heat build up we recommend a post welding cooling cycle of at least four minutes.

Add: 27 GARDEN ROAD, CLAYTON VIC 3168

Phone: 1300 255 935 - 0433 678 234

Email: info@allwelding.com.au

Website: allwelding.com.au